IFLS-600 Insulation Fault Location System is Used in Port and Marine Vessel

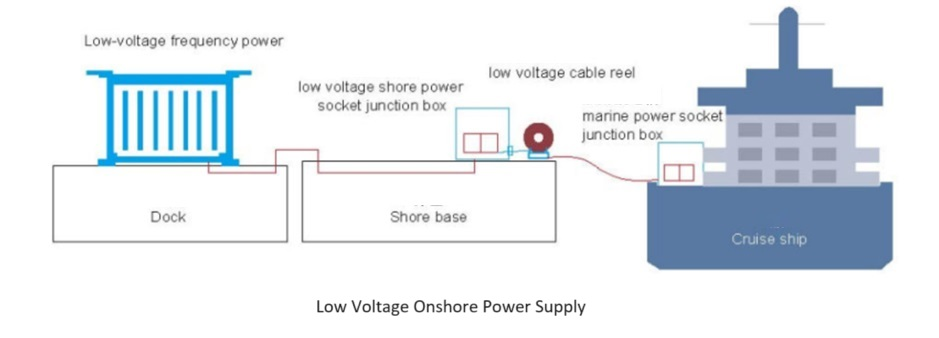

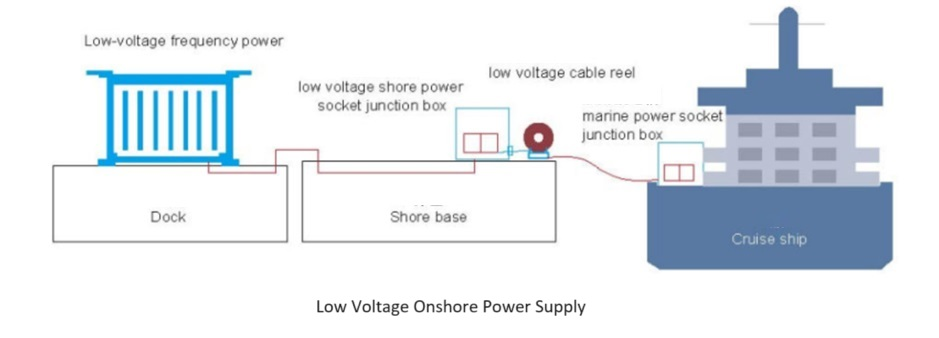

The shore power system refers to the use of land-based power sources instead of diesel engines to directly supply power to cruise ships, cargo ships, container ships, maintenance ships, and other vessels when the ship is docked at the dock. The use of shore power not only reduces pollution emissions and noise pollution when the ship is docked at the port, but also reduces the cost of fuel power generation. The shore power system conforms to the trend of energy conservation, emission reduction, and environmentally friendly development, and the construction of shore power has developed rapidly in recent years.

The requirements for ship electrical systems are not the same. Small coastal ships generally use a 380V 50Hz power grid, while large cargo ships and ocean going ships generally use a 6KV/6.6KV/440V 60Hz power grid. For some large port operation areas, 110kV or 35kV high-voltage electricity will be obtained on the regional power grid, and measures will be taken to reduce it to 3-10kV. After being transmitted from the high-voltage distribution line to the substation, it will be further reduced to 380V distribution voltage before it can be put into use. In summary, the port power supply system generally consists of several parts: regional power grid, step-down substations, port distribution lines, front-end substations, and low-voltage distribution systems.

The shore power system is a complex and comprehensive power consumption system, which inevitably leads to problems such as electric shock, electrical fires, equipment insulation breakdown, and other safety accidents.

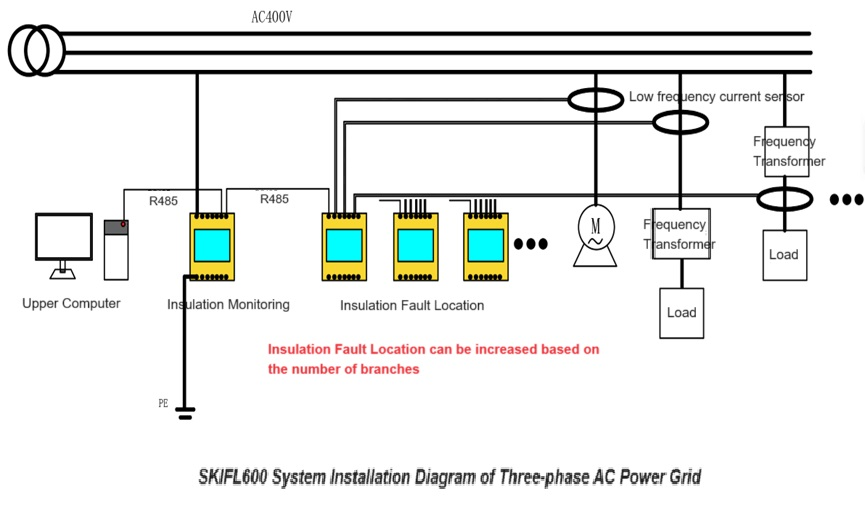

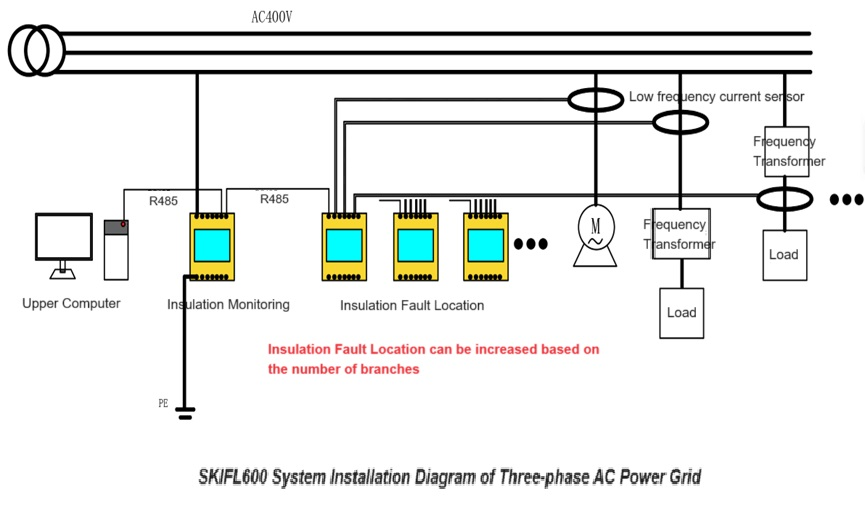

There are many branches of low-voltage electrical equipment in ports, and some electrical and working conditions have high requirements for the continuous power supply and reliability of the power grid. This type of electricity is mainly used in IT systems, which can provide stable transmission. However, ports are high temperature, high salinity, and high humidity environments, and the equipment work intensity is high, resulting in a much faster decline in the insulation performance of equipment and wires compared to normal working conditions, which can easily lead to a decrease in the system's ground insulation and electrical accidents.

The Sikcon's

IFLS-600 insulation fault location system can also be used for insulation monitoring of multi branch and multi load power grids in ports. IFLS-600 can not only monitor the insulation performance of the entire IT power grid, but also locate the problematic branches in case of insulation faults, avoiding manual troubleshooting one by one; Many electrical appliances in ports are non-linear and prone to harmonic generation. Sikcon's IFLS-600 can filter out harmonics and monitor them without being affected by harmonics; High power equipment in ports is frequently used. In order to ensure its normal operation, frequency converters are equipped. For monitoring the load behind the frequency converter, the insulation monitoring instrument may have inaccurate monitoring and misoperation, which is also a difficult problem in the industry. IFLS-600 uses the principle of low-frequency AC measurement to overcome these problems, and can accurately measure the load behind the frequency converter. The equipment installation is simple and flexible. For the increase or decrease of branches in the later stage, SKIFL600 can modular increase the equipment or reduce the number of sensors to meet the demand.